Rockford Industrial Area Revival Project - Moderated newsgroup > Combustion Engine powered machines

> Lincoln welding preheat calculator welder

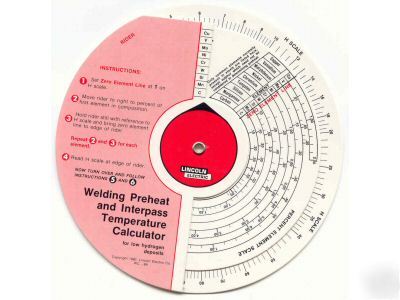

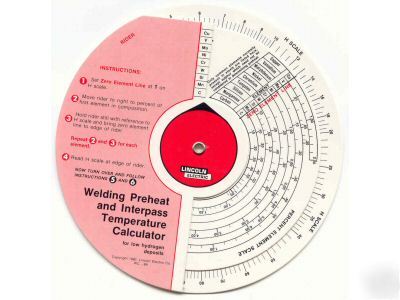

Lincoln welding preheat calculator welder

Lincoln welding preheat calculator welder

From: Polly Oneill

Subject Lincoln welding preheat calculator welder

This is NEW LINCOLN WELDING PREHEAT CALCULATOR.

A simple to use and inexpensive calculator. It is based on practical experience and tends to be very conservative when compared with the TWI method.

1. Reduce the risk of hydrogen cracking

2. Reduce the hardness of the weld heat affected zone

3. Reduce shrinkage stresses during cooling and improve the distribution of residual stresses.

If preheat is locally applied it must extend to at least 75mm from the weld location and be preferably measured on the opposite face to the one being welded.

When hydrogen diffusing from a solidified weld meets a hard microstructure under a tensile stress a crack is likely!

Hydrogen cracking normally occurs in the heat affected zone where hard microstructure is to be found, occasionally it can occur in weld metal.

This is a very searching gas that can be liberated by oil, grease, rust etc. and water under the right conditions.

The greatest risk comes from hydrogen generated within the arc from damp or contaminated welding consumables, mainly fluxes or electrode coatings.

Contamination on the parent metal can also be a risk unless the heat from the welding arc can drive it away. Moisture from condensation on the parent metal will normally be driven off by the heat from the arc before it can get into the weld pool.

Hydrogen in the atmosphere is unlikely to penetrate the arc envelope unless welding is carried out in very damp and humid conditions.

A hydrogen crack can take anything from a few hours to 24 hours to occur. After 24 hours cracking is still possible but less likely, although there have been some reported cases of cracking at 72 hours. It is therefore good practice to allow at least 48 hours before carrying out any NDE.

Hydrogen will eventually disperse from the parent metal, within a few days at room temperature or a few hours if held at around 200?C.

Hydrogen cracking is only possible at room temperature, this is why it is also referred to as cold cracking

A hydrogen crack requires a hard microstructure which is created by a hardenable material subject to fast cooling from 800?C to 500?C. Cooling can be slowed down by:-

* maintaining a high interpass temperature,

* increasing welding power and reducing travel speed.

The heat sink caused by the parent metal thickness and the number of available paths the heat can take to escape, also influence cooling rate. (However once the heat sink reaches a certain size further increases have a negligible effect on cooling rate.). This is why when determining preheat the term combined thickness is used, for a butt weld it is twice the thickness of the parent material and for a T fillet weld three times the thickness.

The hardening of a carbon manganese steel/low alloy steel is influenced primarily by carbon content and to a lesser extent other constituents such as manganese, chrome, silicone etc.

CEIIW = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

Current steel specification do not restrict or limit the Carbon Equivalent and as most steel specs permit a wide range of composition it is possible that one batch of steel may require pre-heat and another may not.

Very low sulphur ( < 0.015%) will increase hardening and special precautions are required when determining the minimum preheat level. Additions of niobium also require special consideration.

Please look at my other items for sale and store!

* If you want Priority Mail - add $2.00.

* I will pack items safe and secure, but I will not be responsible for items lost or damaged in the mail.

* We are not happy unless you are COMPLETELY SATISFIED with your purchase. Thanks.

* Please read description carefully. If you require further information, please e-mail me and I will try to get back to you as quickly as possible. Thanks.

WE LOVE YOUR BUSINESSAND WE WORK EXTREMELY HARD TO MAKE YOU HAPPY. IF YOU ARE UNHAPPY WITH ANY OF OUR PRODUCTS, PLEASE LET US KNOW AND WE WILL MAKE EVERY ATTEMPT TO MAKE YOU SMILE! THANKS AGAIN!

THANK YOU FOR LOOKING AND HAVE A NICE DAY!!

200Amp Tig Torch Parts of Torches Welding Rod 350Amp Tig Torch Welding Supplies Welding Manuals

Contact: Poneill@rockford-industrial.com (Polly Oneill)