Rockford Industrial Area Revival Project - Moderated newsgroup > Agricultural

> Winnebago

> How-to build shop size sheet metal bending brake plans

How-to build shop size sheet metal bending brake plans

How-to build shop size sheet metal bending brake plans

From: Deanna Lane

Subject How-to build shop size sheet metal bending brake plans

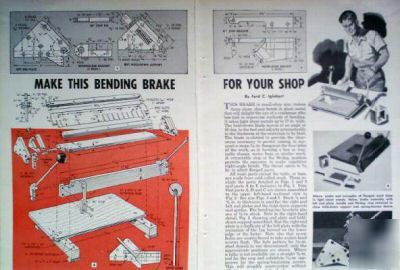

Build a Small-Shop Size Bending Brake

An Original TWO-Page Plan that was removed from a 1958 magazine.

Excerpt: "This brake makes those clean, sharp bends in sheet metal. It takes light sheet metals up to 17 inches wide. The hold-down blade moves at an angle of 45 degrees to the bed and adjusts automatically to the thickness of the materials to be bent. The blade is slotted to provide the clearances necessary to permit raising, in successive steps, 1/2-in. flanges on the four sides of the work, as in forming a box or tray, radio chassis, motor base, or similar work. A retractable stop at the 90-deg. position permits the operator to make repetitive right-angle bends. The throat opens to 5/16 in. to admit flanged parts."

Contact: DLane@rockford-industrial.com (Deanna Lane)